Gianluca Casanova, Global Procurement and Operations Leader at ABB Smart Buildings, explains how the business is embedding circular economy principles

As global industries grapple with mounting environmental pressures and resource scarcity, the role of procurement in driving sustainable transformation has never been more critical.

ABB, one of the world’s leading technology companies, is meeting the challenge head-on through innovative circular procurement strategies that go far beyond traditional waste reduction approaches.

Gianluca Casanova, Global Procurement and Operations Leader at ABB Smart Buildings, is at the forefront of this transformation. With his extensive background in operations management and deep expertise in the electro-mechanical and electronic manufacturing industries, Gianluca is redefining how a global technology leader approaches supply chain sustainability.

Gianluca is helping ABB Smart Buildings on its mission to not simply focus on zero waste goals, but rather embedding circular economy principles throughout its entire procurement ecosystem.

He brings extensive leadership experience in the electro-mechanical and electronic manufacturing industries. With a multi-year track record in strategic procurement and supply chain management, he has demonstrated expertise across operations management, quality management, lean methodologies, continuous improvement, planning, logistics and manufacturing.

Known for his strong leadership capabilities and commitment to people development, Gianluca combines operational excellence with strategic procurement vision to drive organisational success. He holds an Engineer’s degree with a focus in Business Administration, Management and Operations from Politecnico di Milano, providing him with a solid foundation in both technical and business disciplines.

At ABB Smart Buildings, Gianluca leverages his comprehensive background to optimise global procurement strategies, enhance supplier relationships and deliver sustainable value creation across the organisation’s diverse portfolio of electro-mechanical and electronic solutions.

From pioneering partnerships with suppliers to developing recycled materials for safety-critical applications or implementing comprehensive carbon footprint tracking across global supply chains, ABB’s approach under Gianluca’s guidance offers a model for how divisions within global technology companies can drive meaningful environmental impact while maintaining operational excellence and product quality.

ABB has ambitious circular procurement initiatives, but they come with challenges. These include scaling sustainable practices across a global supply chain and understanding how strategic supplier partnerships are enabling breakthrough innovations in materials science.

Here, Gianluca discusses the company’s Mission to Zero framework and the practical steps ABB is taking to achieve its 2030 sustainability targets, including a 25% reduction in Scope 3 emissions.How is ABB approaching circular procurement to go beyond traditional zero waste goals in its supply chain strategies?

Circular procurement at ABB starts with embedding sustainability into product and process design, sourcing and operations.

We’re not just focused daily on reducing ABB’s own emissions and diverting waste from landfill, we’re also sourcing bio-based materials, recycled plastics and green metals, using supplier-provided product carbon footprints to guide decisions.

By integrating these approaches into our global manufacturing platforms – and with every site working towards a verified Zero Waste to Landfill claim by 2030 – we ensure that procurement actively drives Scope 3 reductions and supports both circular economy and decarbonisation goals.

Can you share examples of strategic supplier partnerships ABB has implemented to close the loop on materials and enable a more circular economy?

In Finland, we partnered with Polykemi to use REZYcom PP – a recycled plastic compound – in our junction boxes, cutting carbon footprints by 40% while retaining IP65 performance in sub-zero temperatures.

We’ve also worked with raw material producers on biocircular plastics for our recently launched SAGA range of switches and sockets, and with copper suppliers to recycle our production scrap into new copper supply.

These collaborations prove that high-performance, high quality and safety-critical products can be manufactured with circular materials at scale.

What are the biggest challenges ABB faces in embedding circular principles into global procurement functions and how are you addressing them?

Premium costs for sustainable and ‘green’ materials, limited supplier production

capacity and the long validation and recertification processes for safety-critical electrical products are key obstacles.

We address these by prioritising materials that might not require complete recertification, piloting new product ranges that can be scaled quickly in markets with strong sustainability demand and using our global platforms for efficient rollout.

Mission to Zero – ABB’s framework for achieving net-zero emissions and more sustainable operations – guides our approach by aligning procurement KPIs with environmental goals and enabling robust business cases that balance impact with shareholder value.

What is ABB’s Mission to Zero?

ABB’s Mission to Zero initiative offers a clear blueprint for meaningful change.

Led by Mike Mustapha, Division President of ABB Smart Buildings, the initiative demonstrates how technology, collaboration and a shift in mindset can drive industries towards cleaner, leaner operations.

This ambition is more than corporate rhetoric; it has translated into tangible results across ABB’s global facilities, setting a benchmark for sustainable transformation in industrial operations.

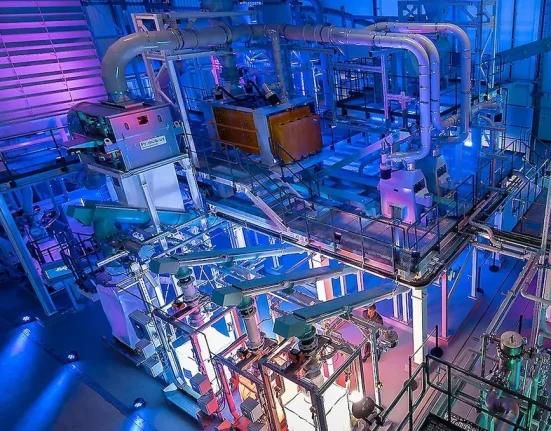

The campaign began at ABB’s Smart Buildings facility in Lüdenscheid, Germany. This pilot project integrated solar panels, electric vehicle chargers and battery storage to create a seamless energy management solution.

The result was an impressive annual reduction of 750 tons of CO₂e emissions. More importantly, it became a scalable model for other sites.

Today, more than 20 ABB facilities have adopted similar strategies, collectively reducing CO₂e emissions by 30,000 tons annually – the equivalent of taking more than 7,000 petrol cars off the road.

Of this, ABB’s Smart Buildings division alone has contributed a 13,000-ton reduction, underscoring the division’s leadership role in the campaign.

How do you measure the impact and success of circular procurement initiatives at ABB, particularly in relation to sustainability targets?

At ABB, we measure the impact of our sustainability initiatives through a structured

and holistic approach. In partnership with EcoVadis, we actively engage tier-one suppliers to track their annual sustainability performance and improvements across key areas: environment, labour and human rights, and ethics and sustainable procurement.

Carbon management is central, particularly the monitoring of Scope 1–3 emissions to assess progress. In parallel, we collaborate with suppliers on primary data collection at product level, including Product Carbon Footprints (PCFs), Life Cycle Assessments (LCAs) and Environmental Product Declarations (EPDs).

Together, these actions support ABB’s 2030 target of reducing Scope 3 emissions by 25%.

What role does innovation in supplier collaboration and materials science play in ABB’s journey towards truly circular procurement practices?

Innovation and commitment to a more resource-efficient future, drive ABB’s journey to circular procurement. By engaging suppliers early in product design and value engineering, we embed circularity and sustainability from the outset.

This collaboration accelerates the adoption of recycled and bio-based materials that meet strict performance and safety standards. Externally-certified Environmental Product Declarations (EPDs) and our EcoSolutions products reinforce transparency, ensuring that new ideas move quickly from pilot to market-ready solutions.

Leave feedback about this